About Us

Dallas Cast Stone is a fourth-generation cast stone manufacturer. We are capable of meeting your project needs both big and small. Our work can be seen across the U.S., adorning one iconic landmark after another. Our service starts with a legendary attention to detail and leads to a promise of excellent work on time.

“Cast stone is both craft and passion.

Its permanence speaks for itself;

its timeless beauty speaks to us all."

Kirk Ragsdale, Third Generation of Dallas Cast Stone

-

BARON RESIDENCE

Baron Residence

This elegant home is built from Texas cream limestone, but cast stone was selected on the accents for its cost effectiveness, plus the ornamentation and design were better suited than limestone. The Baron residence has it all — repetition, detailed ornamentation. We liked the challenge of manufacturing innovative pieces.

Difficulty: One example illustrates the difficulty of the job. The exterior plan of the conservatory called for all of the stone pieces to be designed, modeled and cast in the form of an ellipse. It’s hard to recognize how difficult those pieces were to manufacture by simply looking at a picture of the conservatory.

-

BAYLOR CANCER CENTER

Baylor Cancer Center – Dallas, TX

The Project consists of two featured hardscape areas including the main entrance fountain and a garden area lining the northern property line of the new Baylor Cancer Center building. The primary building product for the hardscape areas is a Cedar Hill Cream limestone. The role of cast stone is a brilliant median to reduce cost on the overall budget of the project.

Cast stone was able to meet the architect’s demand for the extreme radius conditions and ornamental detailing. The beauty of the two products coinciding seamlessly is a testament to the craftsmanship and attention to detail of Dallas Cast Stone. The achievement of a homogenous look between the natural stone and cast stone, while reducing cost for the owner, made the project a success.

-

BANK ONE

Bank One – Ft. Worth, Texas

The 12-story building in downtown Fort Worth follows city officials' objectives to maintain the integrity of the late-19th to early-20th century architecture. This goal was achieved by using a characteristic brick pattern alongside cast stone.

Challenges: The L-shaped soffit panels had to be cast with cores when manufactured. Due to the considerable length of each unit, maintaining a level position during production presented a challenge. For the three-tiered cornices, constructed of very large pieces cantilevered over the building, holes had to be cast into the stone to enable each piece to be bolted to the structure.

Looking for a color that would blend well with the brick matrix of the building, the architect arrived at a one-of-a-kind match that was maintained throughout the project. The signature color of the cast stone and the brick matrix are a perfect melding.

-

CARNEGIE BUILDING

The Carnegie Building

The Carnegie Building was the first high rise in Sundance Square in Fort Worth. This building is a 16-story office building with 280,000-sq-ft of space.

The Carnegie’s first floor offers 12,549 sq ft of retail space. Tenants have direct access to an existing parking structure, as well as Sundance Square operations and security.

-

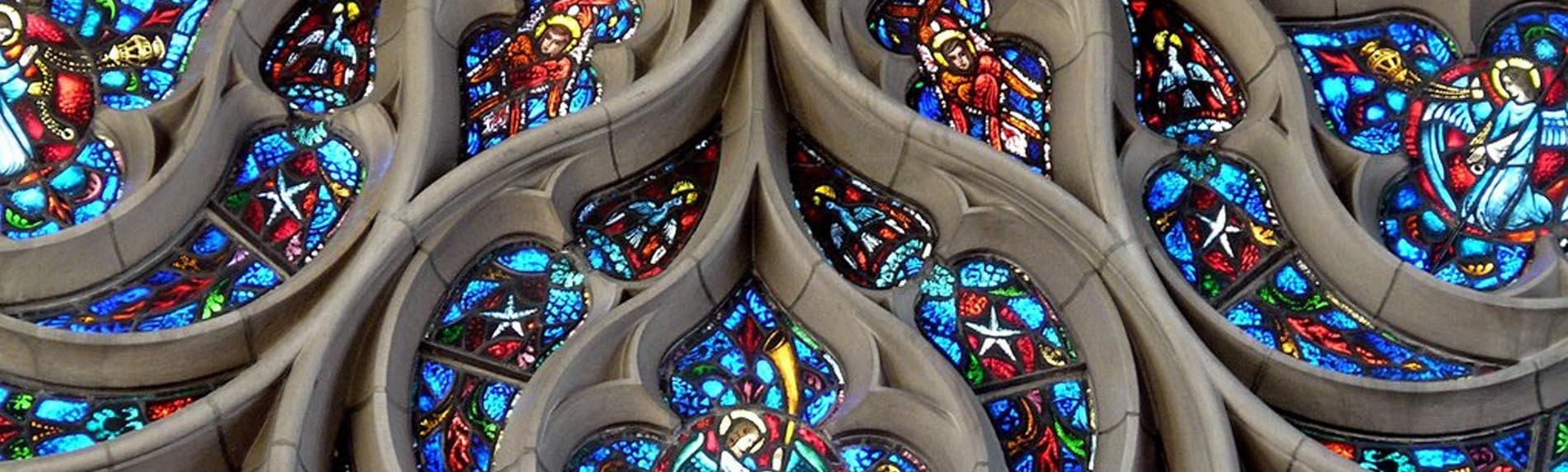

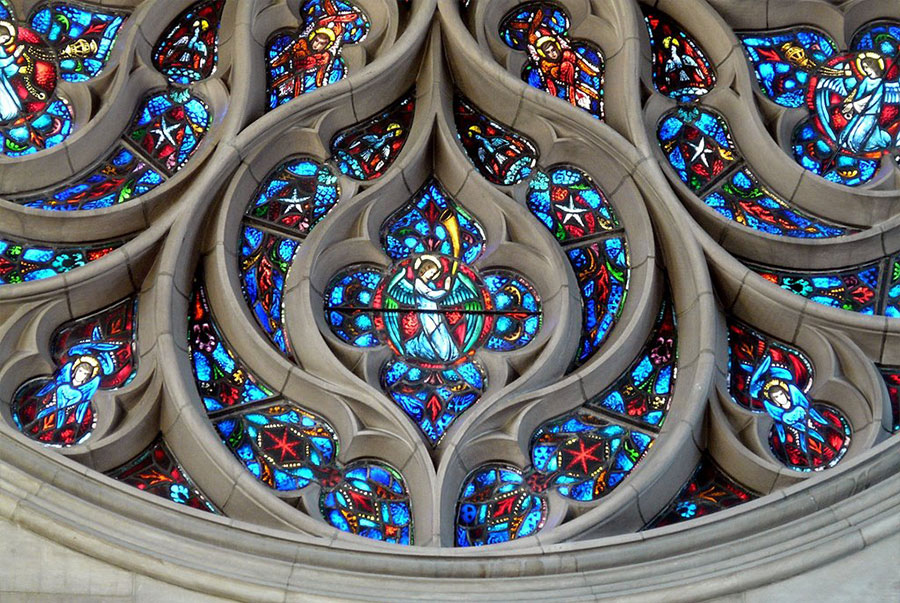

CATHEDRAL OF ST. JOHN

Cathedral of St. John the Evangelist – Spokane, Washington

Construction on this classic gothic structure began in 1925 and utilized limestone from the Seattle area. The restoration would have been expensive with limestone today, but our stone matched the original limestone perfectly. The church never completed tracery windows due to a lack of funds. Last year a donor enabled them to be completed. We worked with Willet Stained Glass Studios, which also helped restore St. Martin's Episcopal Church in Houston.

The stained glass window was held up and outlined by the cast stone, which had to be mixed precisely to match the existing building and original limestone.

Tracing is unique in the design due to the many shapes and radii to make everything flow. We took the original church drawing and incorporated it into a shop drawing. Then we could plot full sizes and make models and molds accordingly.

-

ELLIS COUNTY COURTS

Ellis County Courthouse – Waxahachie, TX

Ellis County Courts and parking garage is a project with masonry clad facades in downtown Waxahachie, TX. Cast stone is used extensively to accentuate the red bricked buildings. The main entrance consists of a stone clad façade and sign.

The entrance doors are recessed and adorned with ornamental header pieces and columns in front. The first floor of the courts building is a split face textured stone. The connecting walkway between the garage and courts building has a split faced, patterned stone wall defining it. The courts roof consists of a solid cast stone enclosure. Remaining elements that accent both the garage and courts buildings are stone sills, headers, copings and medallions.

The building’s color tones and immensity is aesthetically appealing. This project is a perfect example of how a simplistic masonry design can stand out very nicely with the use of cast stone trim and facades.

-

PARK CITIES BAPTIST CHURCH

Park Cities Baptist Church – Dallas, Texas

This addition to a church complex begun in 1948 is the third in four decades, and each features cast stone from Dallas Cast Stone, spanning four decades of Ragsdale family ownership.

There is a higher percentage of cast stone cladding than most buildings, i.e. a radius rotunda on the north and south side.

How cast stone was critical to the project: More than 700 feet of detailed cornices enhance the elaborate community life structure. The project used more than 9,000 cubic feet of material, 5,000 pieces of cast stone and more than 400 forms.A key to success was using cast stone’s unique ability to mimic the architectural style of the original structure and upgrade the facility.

-

SW BAPTIST THEOLOGICAL SEMINARY

Southwestern Baptist Theological Seminary – Ft. Worth, TX

Southwestern Baptist Theological Seminary has been a fixture in Fort Worth since 1910. The new chapel and performing arts center is the primary gathering place for the school. The northeast bell tower is the most prominent feature of the new structure extending to a height of one hundred feet. The tower is elegantly trimmed with proper use of cast stone coping, arches, seals, and columns.

Another stunning masonry design of the project is the arcade arches defined by cast stone columns occurring around much of the building’s perimeter. The cast stone arches which adorn the brick and glass main entrance make for a grand feel when crossing through the front doors. The arches reach a height of twenty two feet and pass through from exterior to interior.

Hardscape features are also a significant part of the project including the Donor Garden. The garden consists of natural stone knee walls capped neatly with a cast stone double bullnose coping. The façade of the new chapel is constructed with brick and cast stone keeping with the tone of other buildings on campus.

-

ST MARTIN'S CATHEDRAL

St. Martin's Episcopal Church – Houston, Texas

This project included a new sanctuary, new Parish Hall and adjoining cloisters on the existing campus.

Elaborate cast stone elements adorn both the interior and exterior and took more than a year to produce. The cast stone accents a beautiful masonry job. The building is perfection in design.

This project was immense in scope, taking four years from concept to completion and countless sessions with the architect, general contractor, mason, steel erector and stained glass firm. It is difficult to put in words all that was involved. My late father, Don Ragsdale, spent hours working out the details to make this project a reality, and I dedicate this job to him.

-

TEXAS CHRISTIAN UNIVERSITY

-

THE RITZ CARLTON

The Ritz Carlton Hotel – Dallas, Texas

This is a 5-star hotel for six floors and continues for 23 more stories as luxury condominium residences, of which 15 percent employ hardscape cast stone enhancements.

The role of cast stone on the project: Exterior cladding, landscape, park and grotto amenities complement the phenomenal Stern design that sets his inspiration apart. We are honored to contribute to the joy of this building.

Cast stone elements include window jambs, 800 pieces; window sills, 1,000 pieces; headers, 300 pieces; ornamental panels, 2,000 square feet; handrail coping, 600 linear feet; pilaster coping, 500 linear feet; spandrels, 2,000 square feet; soffits, 960 square feet; landscape coping, 1,800 linear feet; and poolside coping, 200 linear feet.

How Cast Stone was critical to the success of the project: The brick, pre-cast and cast stone mix provided a stylish finish for the exterior skin of the third through 22nd floors of this splendid new jewel of a building. The cast stone hardscape is a fitting choice for this elegant lifestyle statement in the heart of downtown Dallas.

-

VANDERBILT UNIVERSITY

The Commons - Vanderbilt University – Nashville, Tennessee

This is a five-building, 280,000-square-foot, LEED Silver-certified dormitory on the former (George) Peabody College campus in Nashville. Peabody College was merged into Vanderbilt University in 1979 and is being transformed into a "freshman commons" to provide housing, study and lecture halls for incoming Vanderbilt undergraduates. The cast stone precisely simulates the natural Indiana limestone throughout the Peabody campus, which dates from 1911.

Degree of difficulty: The variegated effect in the cast stone required three color batches and hand mixing into a swirl. Making a percentage of stones a particular hue (and sometimes varied within each piece) proved an artful, painstaking and time-consuming process. The reward was in client satisfaction and the undetected finish of Indiana limestone.